Agentic AI: A Chemical Industry Revolution Already Underway

In a world where everything is changing faster than ever, the biggest change is already happening.

Anyone who has ever seen a sci-fi movie knows that having a computer doing all the day-to-day chores is central to our vision of the future. And now it seems like the future is here, as AI does more and more of the work—everywhere.

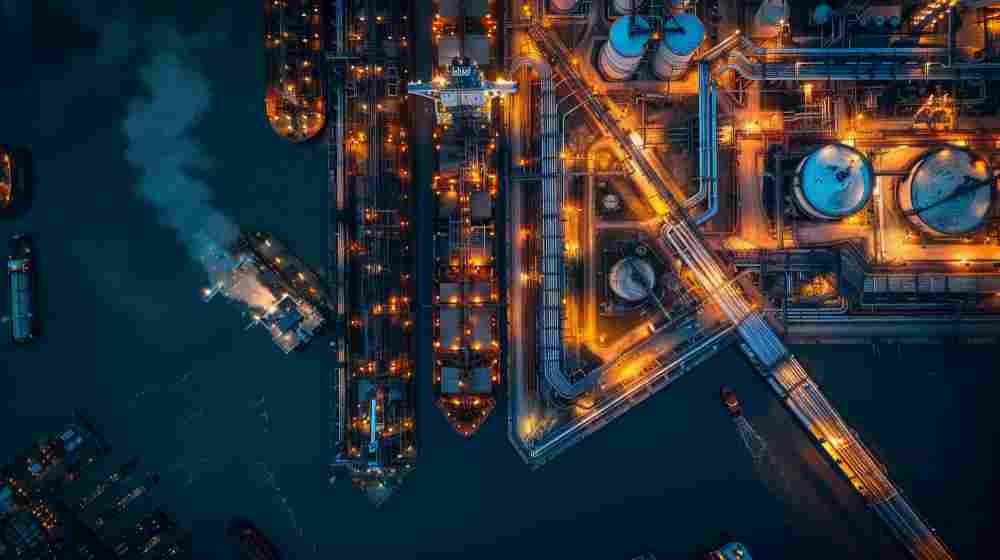

Nowhere is this hitting harder and faster than in the cutting-edge industrial chemicals sector, where saving even a fraction of a percent of energy or raw material input can save a chemical company millions of dollars. For this reason, the application of all-seeing, all-knowing AI which can check, measure, analyse, and report to human command is the next industrial revolution.

In practical terms for the chemical sector, agentic AI is already acting like real colleagues—monitoring processes, proposing solutions, and freeing professionals to focus on higher-value decisions.

What Is Agentic AI?

Agentic AI refers to systems that can act on their own initiative. Instead of waiting for human prompts, they can analyse data, make decisions, and take action. The rise of large language models (LLMs) such as GPT has accelerated their development, giving these agents the ability to reason, interpret natural language, and execute tasks across digital and physical systems.

For the chemical industry—where precision, safety, and efficiency are everything—the potential is enormous with a recent industry survey finding that nearly 80% of chemical industry professionals expect to implement agentic AI soon, and many chemical businesses are already budgeting for it.

But a recent report by Dr. Marc Feldmann, senior principal, Data & AI, Alexander Thamm has outlined where agentic AI is being realised, offering examples of how this technology is no longer science fiction or computer theory, but an actual solution to a more efficient chemical business.

AI Agents on the Factory Floor

US chemicals group Celanese has developed JO.AI, a platform of multiple AI agents that support chemical plant operators across fifty different sites. These agents monitor streams of data—from equipment sensors to maintenance logs—and proactively flag issues such as corrosion or efficiency losses. They can also draft work orders or optimise shift checklists, all through a natural-language chat interface.

Much of the success of the JO.AI is that it is made up of numerous specialist AI system that work as a team as opposed to one giant AI tool. As Feldman explains, “One agent optimises shift checklists. Another flags anomalies – ‘Corrosion might be an issue in heat exchanger 3.’ A third drafts work orders.”

According to Ibrahim Al Syed, director of digital manufacturing at Celanese, the operators, technicians, and managers at the chemical plants are able to communicate with JO.AI in everyday language—just like interacting with a chatbot.

Impressively, the industrial data platform that powers JO.AI integrates data from more than forty sources, including 2.5 trillion records from sensors, apps, and photos. Then ‘knowledge graphs’ aid the AI in making sense of how the chemical processes, machinery, and workforce in each facility are interconnected. While a human is kept in the loop to ensure safety and accountability, the system autonomously surfaces patterns, predicts bottlenecks, and recommends optimisations that would be impossible to detect manually.

AI Agents for Planning & Logistics

A further use of agentic AI is in reshaping chemical production planning. Imagine a suite of AI agents coordinating thousands of customer orders across fifteen chemical plants. A system where one agent tracks supply chain delays, another monitors chemical plant capacity, while a third models ‘what if’ scenarios. Instead of reacting to problems, planners would receive proactive alerts and optimised recommendations in real time.

Feldman describes the system working as follows, “At 7:45 a.m., just as the planner logs in, a notification appears: ‘Potential delivery delay detected for customer HealthCo due to raw material shortfall for order 4715. Estimated risk of SLA breach: 78%. Recommended action: reprioritise order 4719, which uses shared capacity but available stock. Execute?’”

As such agentic AI is helping to avoid problems before they even happen.

AI Agents in the Chemical Lab

Agentic AI’s predictive abilities are also helping at the Pacific Northwest National Laboratory, where chemists are working with CACTUS (Chemistry Agent Connecting Tool Usage to Science) to calculate molecular structure, prioritise experiments, and even adjust procedures based on results.

Using a cutting-edge LLM, researchers can simply type requests into the system in everyday language: ‘simulate this reaction at 200°C’ or ‘suggest a faster route to synthesise compound X.’ This allows human chemists to focus on designing and interpreting experiments, which accelerates discovery in pharmaceuticals, materials, and energy research. Moreover, Feldman notes that CACTUS “is specifically designed to control lab tools directly.” This means that not only is the AI working as an intelligent colleague, but it is also functioning as a lab assistant. “It predicts molecular properties, prioritises experiments, and continuously updates its experimental setups based on results.”

Such is the influence that CACTUS is having in the research of industrial chemistry, that PNNL Chief Data Scientist Kumar has described it as a ‘milestone in the field of cheminformatics.’ A route to improving lab efficiency, by using AI as a tool for making smarter decisions and then allowing it to run experiments autonomously.

These examples show that agentic AI is not a futuristic promise, but a practical tool already reshaping both industrial operations and laboratory research. Whether monitoring thousands of sensors across a global network of chemical facilities or dynamically adapting chemistry experiments, AI agents are stepping into roles that demand speed, precision, and adaptability.

Related articles: Europe’s Plastics Recycling Industry Faces Crisis or Are Online Chemical Trading Platforms Really Any Good?

But the common theme is clear: instead of replacing expertise, they are amplifying it—handling complexity at a scale no human team could manage alone. This means that agentic AI will not replace chemists, chemical engineers, or facility operators, but instead act as colleagues—bringing tireless data analysis, instant recall, and proactive monitoring to complement human judgement.

From discovery labs to production plants to sales and supply chains, the potential for transformation is vast. Because with careful deployment of agentic AI, the chemical industry can usher in an era of faster innovation, more efficient production, and smarter decision-making.

Photo credit: Wirestock, DC studio, Freepik, Freepik, & Lifestyle memory