With uncertain oil prices and ever-tougher limits on fossil fuel emissions modern car designers are aware of the need to make machines that need less fuel. The natural conclusion is to make cars that are lighter, and chemical manufacturers are taking note.

It is well-known that cars are heavy and increasingly expensive to run. A standard steel chassis can weigh as much as 350kg, but by using alternative materials and a chemical composite design that weight falls to as low as 120kg.

Composite cars are already on the market, with the BMW i3 being released a few years ago, and now automobile experts like Alexander Aucken, global automotive manager at Cytec, is predicting the trend to continue, stating, “I would expect this to be adopted more widely over the next 5-10 years.”

This could have a very positive effect on the chemicals industry. As Will Beacham makes clear in his report for ICIS, stating that, “Demand for automotive chemicals could grow significantly over the next 5-10 years if the adoption of carbon fibre for automotive manufacture becomes more widespread.”

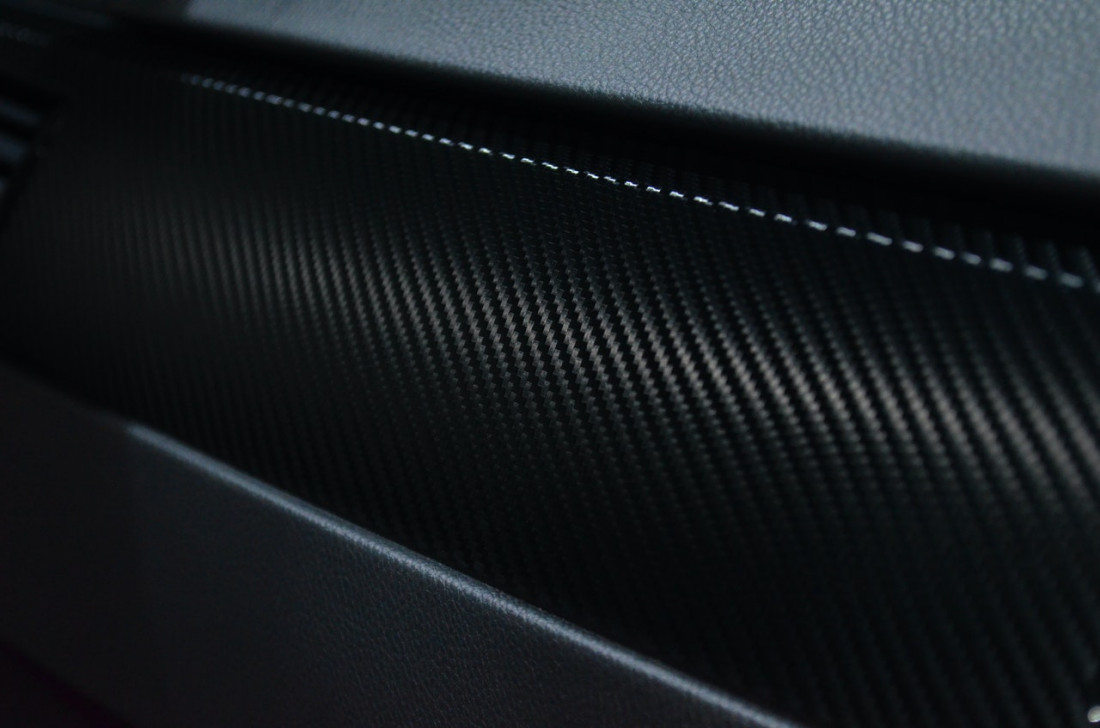

One of the new materials being used in cars is carbon fibre. Cytec uses its own construction that is formulated from a polyacrylonitrile (PAN) precursor that is transformed into carbon fibre by spinning, stretching and heating. The fibres are then mixed with epoxy resins, vinyl esters or other thermoset composites to make pre-impregnated rolls of material that can be cut into the shape desired.

And Cytec is not alone in making a success of this process. Business consultants at CarbConsult predict that “carbon fibre use in the automotive sector could grow from 9,000 tonnes/year in 2011 to between 30,000 and 230,000 tonnes/year by 2022.”

However, there are some drawbacks, as the manufacturing process takes a full 3 to 4 hours using traditional autoclave (pressure and heat in an oven) methods.

As Aucken explains, this technique is not compatible with car manufacturers’ demands. “This [traditional process] is very effective for low-volume parts but if you are making 20,000-50,000 vehicles a year you may need that process to change to have a significant impact on reducing the cost and cycle time to make a part. With a four hour cycle time you would need hundreds of tools for high volumes. Therefore composite materials have been developed which can reduce cycle times to three minutes or less.”

But for this level of manufacture to be maintained, chemical feedstock supplies need to be firmly in place as demand for the required epoxies and thermoset composites rises over the next decade.

As Aucken says, “This supply chain needs to be secured to ensure that risks are managed carefully. Work is going on to ensure this is put in place with plant, equipment and cost models to ensure that there is a guaranteed supply of these materials. We have a lot of relationships with the chemicals and materials supply chain to ensure we will have the volumes we will need for high volume, lightweight manufacture.”

Beyond the next decade, the automotive industry holds many opportunities for the chemicals industry, but it is 3D printing that looks likely to have the biggest impact on how everything is made, including cars.

Cytec is already preparing itself for this market shift, as Aucken states, “We have a 3D printer and are mixing thermoplastic resins with carbon fibre for use in 3D.” Because if this does take off then parts could be printed in a local mechanic’s workshop, rather than having to order them from a factory overseas. This could revolutionise not only car manufacturing, but the chemical industry that supplies it.

With revolution comes opportunity, and with this in mind, some chemical manufacturers and traders are beginning to position themselves in the carbon fibre supply chain for epoxy resins and vinyl esters. How this will affect chemical prices for these products remains to be seen, and who will take best advantage of the situation is also unknown.

As Aucken says, “It’s a hugely exciting opportunity.”