-

Is Populism Hurting the Chemicals Industry?

Continue Reading

Continue ReadingWhen I tell people that I work for a chemical trading company (Spotchemi a.s., as you ask), the most typical response is to make a joke about how I am an illegal drug dealer. While I do sometimes long for the Scarface lifestyle, the reality is far from the cocaine highs of 1980’s Miami.

So why do people misunderstand the chemical industry?

One of the biggest factors is that a minority of people study chemistry beyond the age of 16, but whereas other subjects are largely benign (geography never hurt anyone; geology does hurt but very, very, very slowly), chemicals can have a negative aspect (chemical weapons, chemical plant explosions etc). So even though the negative aspect is less than the smallest fraction of the industry, the powerful images it carries remain.

It is this negative picture, combined with a lack of knowledge that has lead to the public’s fear of chemicals, and a love of all things ‘natural’. This irrational fear is, of course, nonsense, as James Kennedy, a chemistry teacher from Australia, chemophobia combatant, and author of the famous ‘chemical banana’, explains.

“The distinction between natural and synthetic chemicals is not merely ambiguous, it is non-existent. The fact that an ingredient is synthetic does not automatically make it dangerous, and the fact that it is natural doesn’t make it safe. Botulinum, produced by bacteria that grow in honey, is more than 1.3 billion times as toxic as lead and is the reason why infants should never eat honey. A cup of apple seeds contains enough natural cyanide to kill an adult human.”

But, whilst this logic and the banana image are helpful in fighting chemophobia, they do not help de-mystify the subject. Use of chemical names such as botulinum, ethyle-hexanote and histidine mean nothing to the man in the street. Instead it sounds like a reading from Harry Potter’s spell book, and increases public perception of industrial chemists as a mix of mass-murderer and a sorcerer.

Maybe the chemical industry needs a better understanding of the problem. The popular blogger, chemjobber, writes that, “Ultimately, this is a problem of psychology. In the age of high-investment parenting, threats to our children can overrun any rational defence a parent might be able to construct. For whatever reason, chemical risk seems to appear much more threatening to some parents. As a chemist, I find chemophobia pretty ridiculous. As a parent, I’m in sympathy — we all fear unknown threats to our kids.”

This is a very understandable situation, and one that education could help prevent, however the chemical industry lacks a unified system to explain its actions. It is a group of hundreds of thousands of companies that merely share a common goal of providing a much derided product.

Meanwhile, anti-chemical activists are growing in stature based on a wave of populism that makes wild, easily comprehensible claims. Slogans, online quotes and gifs which state easy solutions to problems, such as ‘all Monsanto products are bad’, ‘Modern beer is chemical soup’ or the now famous, ‘There is just no acceptable level of chemical to ingest, ever.’

This last one was said by the famous healthy-living, detoxifying-guru, Foodbabe (pictured), a computer science graduate who has seen great success in various campaigns to have certain ingredients removed from food. For example, she brought wide-spread media attention to the use of the oxidizing agent and dough conditioner azodicarbonamide in bread products sold at Subway, McDonald’s and other well known brands. Such was the negative publicity that, rightly or wrongly, most retailers had the product removed from their recipes. One of the keys to the argument was that azodicarbonamide was also used to make the bubbles in yoga mats, and was therefore a bad ingredient for food.

This must have had a devastating impact on some food chemical traders and manufacturers, and might make other chemical producers wonder where the media spotlight will fall next. Lazy science and ‘bad by association’ logic benefits no one, and instead only creates a culture of unnecessary fear. For example, the self-styled ‘food babe’ [real name Vani Hari] has also complained about the quality of air inside passenger aircraft, claiming that, “The air that is pumped in isn’t pure oxygen either; it’s mixed with nitrogen, sometimes almost at 50%.”

If you want a further laugh you can take the ‘Food Babe quiz’ at Chemistry Blog “Can you tell Vani Hari quotes from other irrational nonsense?”

While to the informed the thinking behind such statements is hilarious, it can cause fear and panic to the less-educated.

Meanwhile, the battle for sensible science and a better understanding of the chemical industry loses further ground. How this war will be won is not yet known. Chemistry is a complex field, and if pop-science is making headway with catchy phrases such as, ‘if you can’t pronounce it, don’t eat it’. Then perhaps the chemical industry should fight back with some slogans of its own. As the online media reviewer ‘Whatculture’ cleverly suggests, “Perhaps a better tagline would be “If you can’t pronounce it, and you think it is cause for concern, learn to pronounce it and educate yourself on its effects in order to make an informed decision.”

But that’s not so catchy, is it?

Photo credit: James Kennedy

Photo credit: YouTube/the good life project

-

How Boron at the Atomic Level could be Better than Graphene

Continue Reading

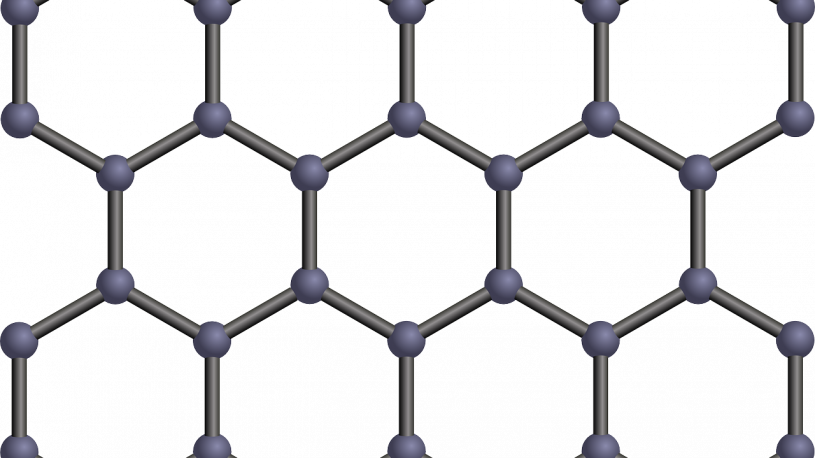

Continue ReadingYou don’t need a doctorate in chemical engineering to know that graphene is the material of the future. We’ve all been told how the all-powerful, single atomic-layer of graphite will change the world, just as soon as we master industrialized production.

And given the money being spent on research, this may be just a matter of time, especially as the possible applications are so far-reaching. For example, a BBC report on graphene noted its extensive list of potential uses, including, “Flexible electronic screens … a ‘thin paint’ that acts as a rust protector … an ‘electronic ink’ … act as a sensor for measuring strain, gas, magnetism or pressure … aiding drug delivery … regenerative medicine … additive for advanced composite materials to make them impermeable or conductive or stronger…[and even] ‘e-paper.’”

But all that might be about to change, as researchers from Rice University, have published findings in the Journal of American Chemical Society that outlines how a single atomic-layer of boron may prove to be a more resourceful substance.

In their computer-simulation experiments, the online scientific journal Phys.org reports, how they theorized that, “if metallic ribbons of boron are stretched, they morph into antiferromagnetic semiconducting chains, and when released they fold back into ribbons.” And also that, “The 1-D boron materials also have mechanical stiffness on a par with the highest-performing known nanomaterials.” As well as the fact that, “they can act as nanoscale, constant-force springs.”

The report continues to describe how, “One-dimensional boron forms two well-defined phases—chains and ribbons—which are linked by a ‘reversible phase transition’, meaning they can turn from one form to the other and back.

The title picture to this article shows a series of stills from a simulation of the properties of one-dimensional boron. It shows how the material starts as a ribbon transforms into a single-atom chain, until it reaches the breaking point.

You can watch a video of the experiments on this YouTube clip.To demonstrate these interesting chemomechanics, the researchers used a computer to ‘pull’ the ends of a simulated boron ribbon with 64 atoms. This forced the atoms to rearrange into a single carbyne-like chain. In their simulation, the researchers left a fragment of the ribbon to serve as a seed, and when they released the tension, the atoms from the chain neatly returned to ribbon form.”

“Boron is very different from carbon,” said lead researcher Boris Yakobson, Professor of Materials Science and NanoEngineering and Professor of Chemistry at Rice University. “It prefers to form a double row of atoms, like a truss used in bridge construction. This appears to be the most stable, lowest-energy state. [So] If you pull on it, it starts unfolding; the atoms yield to this monatomic thread. And if you release the force, it folds back.”

“That’s quite fun, structurally, and at the same time it changes the electronic properties. [Which makes for] an interesting combination. Because when you stretch it halfway, you may have a portion of ribbon and a portion of chain, [but] because one of them is metal and the other is a semiconductor, this becomes a one-dimensional, adjustable Schottky junction.”

A Schottky junction is a barrier to electrons at a metal-semiconductor junction and is commonly used in diodes that allow current to flow in only one direction.

Furthermore, the ability to couple magnetic state and electronic transport in the same material will be of great interest to researchers of spintronics, a state-of-the-art form of electronics that is thought to be key to the creation of future high-performance electrical devices.

“It may be very useful because instead of charge transport, you can have spin transport. That’s considered an important direction for devices that make use of spintronics,” said Yakobson.

Given the importance that nano-materials are expected to play in all our futures, the ability to control electronics on a nano-level with a material as small as an atomic-layered sheet or single ribbon of boron could prove priceless.

While for now the findings are only theoretical, the computer simulations conducted at Rice University were also able to predict the nature and possibility of carbon-atom chains known as carbyne, as well as boron fullerenes and two-dimensional films called borophene, all of which are now a reality having been successfully predicted by the Rice computer simulations.

But in the true spirit of cutting edge material science, the research team remains excited by their dicovery, even if it will take many years to become a practical reality. As Yakobson explains, “Even if they never exist, they’re still important since we’re probing the limits of possibility, a sort of the final frontier.”

photo credit: Yakobson Group/Rice University

-

Nano Particle Fertilizer that Can Halve Fertilizer Use

Continue Reading

Continue ReadingOne of the biggest problems of any agricultural product, but especially fertilizer, is run-off. That’s a lot of time, crop assistance, and money that simply doesn’t make it to the plant, and instead pollutes nearby eco-systems. But now a team of agrichemical researchers claims to have made a major breakthrough by coating the urea the plant needs onto nano-particles of an organic mineral called hydroxyapatite. Early field results on rice indicate that the method can halve fertilizer usage through the technique’s slow release system.

The online journal, ScienceDaily, outlined the problem, stating that, “Farmers often use urea, a rich source of nitrogen, as fertilizer. Its flaw, however, is that it breaks down quickly in wet soil and forms ammonia. The ammonia is washed away, creating a major environmental issue as it leads to eutrophication of water ways and ultimately enters the atmosphere as nitrogen dioxide, the main greenhouse gas associated with agriculture. This fast decomposition also limits the amount of nitrogen that can get absorbed by crop roots and requires farmers to apply more fertilizer to boost production.”

While coating nano-particles with chemicals has been known by chemical engineers as a useful tool for a long time, until now the method has largely been confined to the pharmaceutical industry. However, little research has been done to use it as a way to apply chemicals to crops, which is surprising given the global expenditure on fertilizer and the problems much of the third world, often living on land that needs fertilizer the most, has in buying sufficient agricultural products.

But now a team has outlined the revolutionary process in a press release to the American Chemical Society, which states how, “The researchers developed a simple and scalable method for coating hydroxyapatite (HA) nanoparticles with urea molecules. HA is a mineral found in human and animal tissues and is considered to be environmentally friendly. In water, the hybridization of the HA nanoparticles and urea slowly released nitrogen, 12 times slower than urea by itself.”

The full report has now been published in the journal ACS Nano, which explains how in the study, “the high solubility of urea molecules has been reduced by incorporating it into a matrix of hydroxyapatite nanoparticles. Hydroxyapatite nanoparticles have been selected due to their excellent biocompatibility while acting as a rich phosphorus source. In addition, the high surface area offered by nanoparticles allows binding of a large amount of urea molecules. The method reported here is simple and scalable, allowing the synthesis of a urea-modified hydroxyapatite nanohybrid as fertilizer having a ratio of urea to hydroxyapatite of 6:1 by weight. Specifically, a nanohybrid suspension was synthesized by in situ coating of hydroxyapatite with urea at the nanoscale. In addition to the stabilization imparted due to the high surface area to volume ratio of the nanoparticles, supplementary stabilization leading to high loading of urea was provided by flash drying the suspension to obtain a solid nanohybrid. This nanohybrid with a nitrogen weight of 40% provides a platform for its slow release.”

It is this slow release that allows the Sri Lankan based team to report that, “Initial field tests on rice farms showed that the HA-urea nanohybrid lowered the need for fertilizer by one-half.”

The research was based on the team’s earlier work from 2011, which had already established the potential success of a system where, “urea-modified hydroxyapatite nanoparticles were encapsulated under pressure into cavities of the soft wood of Gliricidia sepium.” This “urea-modified HA nanoparticle-encapsulated Gliricidia sepium nanocomposite” was then applied to the soil and gave a more effective release of nitrogen than the control commercially available fertilizer. As shown in the graphic below.

You can download a copy of this earlier 2011 study on pdf here.

While it is still too early to claim that global fertilizer sales can be expected to be halved, the research is finding significant interest among agricultural specialists. Seemingly the process is easily scalable, and the new product applicable to all major crops. The technique also includes the added bonus that using Hydroxyapatite will act as a source of phosphorous.

Further testing is now required, before all parties are satisfied of the success of the method. But if it is verified that the process leads to a 50% reduction in fertilizer use, then all agrichem dealers and urea traders might be asking is, “Can I double the price?”

Photo credit: Guru Ghasidas University, India