-

What the EU-UK Trade Deal Means for the Chemical Sector

Continue Reading

Continue ReadingThe UK and EU have now signed a significant agreement aimed at resetting their post-Brexit relationship. It is a long-awaited deal following years of resentment and a lack of political will to establish common ground following the UK’s decision to leave the EU.

Unfortunately for the chemical industry, the deal does little to ease the burden of red tape created when the UK left the customs union. Instead, the deal’s highlight appears to be the Sanitary and Phytosanitary (SPS) agreement, which simplifies the export and import procedures for food and agricultural products. Although it is a provision which primarily targets the agrifood sector, the principles of reduced checks and streamlined processes may, possibly, set a precedent for similar arrangements in the chemical sector, facilitating smoother trade in the future.

But there is other good news for British business as the deal also eases cross-channel energy trading. This could go some way to lowering electricity prices where UK manufacturing sectors, such as the chemical industry, pay some of the highest rates in Europe.

However, the best announcement for companies who import and export industrial chemicals between the UK and EU has been the assistance the deal provides on carbon taxes. As Stephen Phipson, head of the manufacturers’ organisation Make UK, notes, “The agreement that the UK and EU will link their carbon markets to avoid taxes on carbon-intensive goods like steel and cement [and chemicals] travelling between the UK and EU is welcome news.”

A further central component of the new agreement is the mutual recognition of conformity assessment (MRCA). This provision allows products certified in one jurisdiction to be accepted in the other, reducing redundant testing and compliance costs. For the chemical industry, this means streamlined processes for certifying products, potentially accelerating time-to-market and reducing administrative burdens.

However, many are reserving judgement on the deal until they have read the small print and seen it in action, such as Steve Parker, the director-general of the British International Freight Association (BIFA), who stated that, “It is now down to government to work out the most practical solutions.”

For its part, the UK’s Chemical Industries Association (CIA) has also expressed cautious optimism regarding the deal, stating that, “The potential platform offered by today’s announcements are where we need to be.”

It applauded the commitments to ease the electricity market but awaited full comment until the details have been checked, especially that made over the Emissions Trading Scheme (a.k.a. carbon tax).

“The Emissions Trading Scheme link might pave the way to a long-lasting solution but in considering options for linking it is important that any solution is adequate and aligned to deliver decarbonisation not deindustrialisation,” the Association said in its press release. “Above all of this, whatever deal is or is not reached, the UK Government must ensure policy and economic stability so that chemical manufacturing sites in the UK who are competing with sites around the world, can attract investment in net zero technologies.”

Certainly, the European chemical sector needs some support. A recent survey of members of the Chemical Business Association in November 2024, found that, “71% faced chronic import/export challenges, while 82% were concerned by regulatory uncertainty.”

As such, any trade deal which eases access to transnational markets will be seen in a productive light. But despite the positive aspects, the chemical industry still faces challenges. The need to comply with both UK and EU regulations remains a significant administrative burden, leading to increased costs for businesses. Small and medium-sized enterprises (SMEs), in particular, may find it difficult to navigate the complexities of dual regulatory systems.

Related articles: Six Trends in Industrial Chemical Online Marketplaces or How Can Chemicals Trading be Made More Efficient?

For while the MRCA and SPS agreements offer benefits, they do not fully address issues related to the UK’s divergence from the EU’s Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation. Without full alignment, UK chemical companies may still face barriers when accessing the EU market, potentially limiting the effectiveness of the new deal.

Overall, it is felt that the newly signed UK-EU deal presents opportunities for the chemical industry by facilitating trade and reducing certain regulatory burdens. Yet while it marks a positive move towards improved relations and economic growth, continued efforts are necessary to fully resolve the complexities faced by chemical companies operating between the UK and EU markets.

Nothing can replace the boost to business which the chemical industry enjoyed with the barrierless trade of Britain being a member of the EU. As a result, the overwhelming sentiment is one of gratitude that finally the two sides are speaking proactively again and have made a business-friendly deal—however small that may be.

For example, despite the farming and food sectors being one of the biggest winners in the trade deal, even the president of the Northern Ireland farmers’ union, the UFU, remains wary of celebrating too loudly. “This deal isn’t going to remove all obstacles overnight,” he said. “It will take up to 18 months to implement, and much of the content will be complex and require further clarification. But it is,” he concludes, “a step in the right direction.”

Good news for traders of industrial chemicals? The answer, it seems, is a cautious “yes.”

Photo credit: Benny Sun on Unsplash, Chelaxy Designs, Julia Taubitz, & Starline on Freepik

-

Six Trends in Industrial Chemical Online Marketplaces

Continue Reading

Continue ReadingTraditionally, chemical sales relied heavily on direct interactions and manual processes. However, online chemical marketplaces have emerged as crucial venues for buyers and sellers of raw materials in the rapidly changing world of business-to-business interactions.

These chemical trading hubs are making it easier to communicate, negotiate, and make transactions effectively, such that they have become central to manufacturers’ feedstock sourcing.

Yet looking to the future, B2B chemical marketplaces are about to be transformed by several key trends. These include:

1. Improved Transparency and Traceability

Chemical industry transparency and traceability has become crucial as consumers look for products from ethical and sustainable sources. At the same time, proposed EU regulations are expected to impose complete raw material to disposal trackability for all industrial chemical products.

In response to these law changes alongside trends in consumer demand, B2B chemical marketplaces are now offering greater openness and documentation. In this sense, chemical trading hubs are differentiating themselves through collaborating with suppliers who meet strict sustainability requirements. B2B online markets enable procurement departments to make well-informed decisions and match company values with their purchases by providing thorough product information, such as certification and origin information.

2. IoT and Supply Chain Management

Chemical company supply chain management is expected to be completely transformed by the Internet of Things (IoT). In order to maintain inventory levels, keep an eye on storage conditions, and facilitate real-time order tracking, B2B markets are anticipated to incorporate IoT devices and sensors to allow for speedy procurement of stock.

This degree of connectedness guarantees improved inventory control, lowers waste, and boosts overall operational effectiveness. For this reason, industrial chemical stakeholders are leading the way in deploying IoT solutions to streamline the trade process because they recognise the value of a smooth supply chain.

3. Promotion of Sustainable Practices

B2B chemical marketplaces are also playing a pivotal role in advancing sustainable practices and supporting the transition to a circular economy. By creating digital platforms where surplus, excess, or off-spec chemicals can be resold or repurposed, these marketplaces help reduce the volume of chemical waste that might otherwise be incinerated or sent to landfill. This not only minimises environmental impact but also enables chemical businesses to recapture value from unused inventory, turning potential losses into revenue streams.

Moreover, many of these platforms actively promote sustainable sourcing by partnering with suppliers who meet recognised environmental and ethical standards. This allows buyers to make more informed decisions aligned with corporate sustainability goals.

In addition, by offering detailed product information—such as origin data, carbon footprint, lifecycle analysis, and disposal guidance—these marketplaces empower procurement professionals to evaluate products not just on cost and performance, but also on their long-term environmental and social impact. Through these efforts, B2B chemical marketplaces are helping to embed sustainability into the core of industrial procurement strategies, making it easier for companies across the chemical value chain to operate more responsibly and efficiently.

4. Artificial Intelligence

The impact of AI is being increasingly felt across all sectors of the economy, but nowhere more so than the chemical industry. Similarly, B2B industrial chemical markets are expected to undergo a transformation as a result of the integration of AI technologies. AI algorithms can improve individualised purchasing experiences, suggest relevant products, and expedite search procedures by utilising data analytics. Advanced AI algorithms that examine customer preferences, historical data, and market patterns are being adopted by industrial chemical marketplaces. This makes it possible for them to offer individualised advice, streamline the purchasing procedure, and give a flawless user experience.

5. B2B Markets Span Geography

Geographical limits are being removed via B2B chemical marketplaces, enabling companies to enter new markets and increase their market share. Industrial chemical marketplaces are giving companies the chance to explore the whole world for sourcing feedstocks, establishing connections, and doing business with chemical industry professionals from anywhere on the planet. This improved accessibility encourages healthy competition, sparks creativity, and creates opportunities for win-win partnerships on a global scale.

6. Customization in Chemical Markets

Industrial chemical sales have traditionally been customised through personal relationships built up over time between chemical suppliers and buyers. Originally, online chemical markets focused on their advantages of speed, ease of use, price comparison etc.

Now B2B chemical platforms are adding value-added services and customisation choices to differentiate themselves in a crowded industry. By providing extra services like quality checks, lab testing, and product customisation, industrial chemical markets are moving beyond the traditional transactional model. Instead, they are modernizing sales and marketing processes by offering solutions that connect the entire buying process—from research to reordering.

Thanks to these value-added services, online B2B markets are positioned as a reliable and all-inclusive platform for chemical trading. They are giving buyers more assurance in their purchases while also facilitating smoother procurement processes.

In conclusion, B2B chemical marketplaces are not just reshaping how industrial chemicals are bought and sold—they are redefining the very nature of business in the chemical sector. As these platforms continue to evolve, the integration of AI, IoT, enhanced transparency, global accessibility, and customisation is setting new standards for efficiency, sustainability, and user experience. By embracing these innovations, chemical marketplaces are poised to become indispensable tools for modern procurement, fostering stronger, more informed, and more agile connections between suppliers and buyers worldwide.

As such, the future of industrial chemical trade lies not just in digital convenience, but in the smart, transparent, and collaborative systems offered by B2B online chemical trading hubs.

-

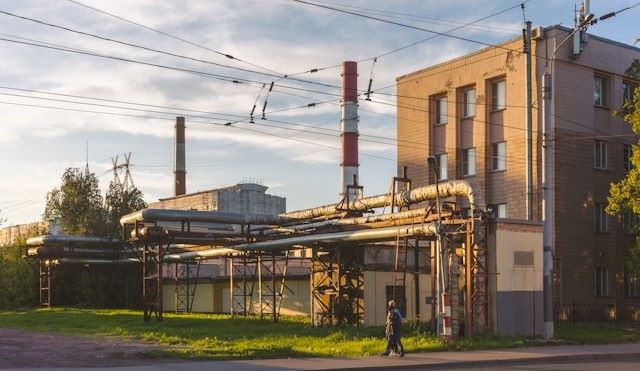

Czech Chemical Industry Calls for Limit on Russian Imports

Continue Reading

Continue ReadingSince sweeping sanctions were imposed on Russia following its invasion of Ukraine, Europe’s chemical industry has been caught in a life-threatening dilemma.

The once all-powerful producer of global chemical output had been heavily reliant on Russian energy and raw materials. Now that geopolitics is attempting to cut off the supply of low-cost power and chemical feedstock, the European chemical sector is now having to cope with soaring input costs, disrupted supply chains, and an urgent need to recalibrate its sourcing strategies.

While the sanctions are believed to be hurting Moscow’s revenues and limiting further aggression, they are having unintended consequences closer to home—particularly in Germany, the EU’s chemical powerhouse.

Before the war, Russian natural gas played a crucial role in fuelling Europe’s energy-intensive chemical plants, from fertiliser manufacturers to plastics producers. But with imports now drastically reduced or cut off entirely, companies are facing not only higher prices but also structural vulnerabilities that threaten their global competitiveness.

This is particularly painful as the European chemical industry is currently also trying to survive a wave of cheaper chemical imports from Asia, North America, and the Middle East, while also handling a sluggish domestic economy experiencing a steady decline in manufacturing output. At the same time, the EU’s green transition ambitions are adding further pressure, leaving the industry at a crossroads: adapt rapidly or risk long-term decline.

One example of the pain being felt can be seen in the Czech chemical industry, which (for a country of only 10 million people) employs a healthy 130,000 workers in its chemical sector. However, according to Ivan Souček, the director of the Association of the Chemical Industry of the Czech Republic, its chemical companies are going through a painful transition.

“The development plans of most of the key players in the Czech chemical industry have been revised,” he explained. “The drop in employment in the chemical industry could range from 11,000 to 32,000 people in the next few years, although the possibility of their partial use in the newly emerging ‘green industries’ can be considered.”

One Czech chemical company which is already feeling the pinch is SPOLANA, part of the ORLEN Unipetrol group and a manufacturer of PVC, caprolactam, and ammonium sulphate (for industrial fertilizer), as well as inorganic compounds and other chemical products. As recently the company had to lay off 550 workers out of almost 700 who were employed at SPOLANA’s main chemical facility just outside Prague.

Other chemical companies in Europe are also feeling the economic squeeze. In Germany, for example, SKW Piesteritz was forced to close one of its two ammonia production plants, citing, “market and political conditions.”

The unfavourable market situation is largely due to the wholesale import of Russian fertilizers which are driving down prices to an unprofitable level for European chemical producers.

As Peter Tsingr, the deputy chairman of Agrofert (fertilizers and fuel), recently stated, “… the whole of Europe, from Poland to France, is flooded with Russian fertilizers: they are imported by sea, and from ports these goods enter Europe.”

Tsingr went on to highlight that so far, central European countries had been somewhat protected from these imports due to their inland location. “Transportation costs money,” he said. “Russian exports were here even before the conflict in Ukraine, but in Germany, for example, it has grown six times, and in Central Europe — three times. About 15% of fertilizers on the Czech market come from Russia.”

Consequently, representatives of the Czech chemical industry are asking for government assistance in restricting further fertilizer imports from Russia if further European chemical plant closures are to be prevented. They cite the fact that the EU is limiting Russian natural gas imports, but is doing little to restrict its derivatives.

“Through fertilizers, the main raw material for which is natural gas, gas is actually imported further and with more added value for Russian producers,” Souček explains. “Moreover, we are economically destroying the European industry, because European manufacturers can’t seriously compete with Russian ones.”

The call to action is likely to receive a positive response from the Czech government which has long called for stricter sanctions on Russia—up to and including a complete ban on Russian goods and services entering the EU. However, as a trading bloc, the final decision on what chemical products can and cannot be imported lies with the politicians in Brussels.

Notably, the EU’s final push to remove Russian energy and chemical feedstock imports is proving a challenge. As a recent Reuters report notes, “While EU imports of Russian gas via pipelines have plummeted since the invasion of Ukraine in February 2022, around 19% of the bloc’s gas imports still comes from Russia through liquefied natural gas imports and via the TurkStream pipeline into central Europe.”

All the same, Brussels remains publicly committed to punishing Russia for its aggression, even if it economically also hurts domestic economic health. As Reuters explained, “The European Union last week released a roadmap for fully phasing out Russian oil and gas imports and the European Commission next month will propose legal measures to ban remaining Russian pipeline gas and LNG imports under existing contracts by the end of 2027. [Furthermore], the EU executive body will also propose a ban on new deals for Russian gas and existing spot contracts by the end of 2025.”

Ultimately, Europe’s chemical industry stands at a crossroads. What began as a geopolitical move to curb Russian aggression has evolved into a far-reaching economic challenge for one of the continent’s most vital industrial sectors. As chemical companies battle rising costs, foreign competition, and mounting regulatory pressures, the future of European chemical production hangs in the balance.

Without swift, coordinated action—whether in the form of targeted trade restrictions, strategic support for affected industries, or accelerated investment in sustainable feedstock alternatives—Europe risks not only losing a key economic pillar but also deepening its dependence on the very imports sanctions sought to eliminate.

As a result, the decisions made in Brussels over the coming months will not only shape the chemical industry’s trajectory but will also define Europe’s industrial resilience in an increasingly unstable world.

Photo credit: Wirestock on Freepik, Gencraft, Gencraft, Red Shuheart on Unsplash, & Mark Tryapichnikov