Since sweeping sanctions were imposed on Russia following its invasion of Ukraine, Europe’s chemical industry has been caught in a life-threatening dilemma.

The once all-powerful producer of global chemical output had been heavily reliant on Russian energy and raw materials. Now that geopolitics is attempting to cut off the supply of low-cost power and chemical feedstock, the European chemical sector is now having to cope with soaring input costs, disrupted supply chains, and an urgent need to recalibrate its sourcing strategies.

While the sanctions are believed to be hurting Moscow’s revenues and limiting further aggression, they are having unintended consequences closer to home—particularly in Germany, the EU’s chemical powerhouse.

Before the war, Russian natural gas played a crucial role in fuelling Europe’s energy-intensive chemical plants, from fertiliser manufacturers to plastics producers. But with imports now drastically reduced or cut off entirely, companies are facing not only higher prices but also structural vulnerabilities that threaten their global competitiveness.

This is particularly painful as the European chemical industry is currently also trying to survive a wave of cheaper chemical imports from Asia, North America, and the Middle East, while also handling a sluggish domestic economy experiencing a steady decline in manufacturing output. At the same time, the EU’s green transition ambitions are adding further pressure, leaving the industry at a crossroads: adapt rapidly or risk long-term decline.

One example of the pain being felt can be seen in the Czech chemical industry, which (for a country of only 10 million people) employs a healthy 130,000 workers in its chemical sector. However, according to Ivan Souček, the director of the Association of the Chemical Industry of the Czech Republic, its chemical companies are going through a painful transition.

“The development plans of most of the key players in the Czech chemical industry have been revised,” he explained. “The drop in employment in the chemical industry could range from 11,000 to 32,000 people in the next few years, although the possibility of their partial use in the newly emerging ‘green industries’ can be considered.”

One Czech chemical company which is already feeling the pinch is SPOLANA, part of the ORLEN Unipetrol group and a manufacturer of PVC, caprolactam, and ammonium sulphate (for industrial fertilizer), as well as inorganic compounds and other chemical products. As recently the company had to lay off 550 workers out of almost 700 who were employed at SPOLANA’s main chemical facility just outside Prague.

Other chemical companies in Europe are also feeling the economic squeeze. In Germany, for example, SKW Piesteritz was forced to close one of its two ammonia production plants, citing, “market and political conditions.”

The unfavourable market situation is largely due to the wholesale import of Russian fertilizers which are driving down prices to an unprofitable level for European chemical producers.

As Peter Tsingr, the deputy chairman of Agrofert (fertilizers and fuel), recently stated, “… the whole of Europe, from Poland to France, is flooded with Russian fertilizers: they are imported by sea, and from ports these goods enter Europe.”

Tsingr went on to highlight that so far, central European countries had been somewhat protected from these imports due to their inland location. “Transportation costs money,” he said. “Russian exports were here even before the conflict in Ukraine, but in Germany, for example, it has grown six times, and in Central Europe — three times. About 15% of fertilizers on the Czech market come from Russia.”

Consequently, representatives of the Czech chemical industry are asking for government assistance in restricting further fertilizer imports from Russia if further European chemical plant closures are to be prevented. They cite the fact that the EU is limiting Russian natural gas imports, but is doing little to restrict its derivatives.

“Through fertilizers, the main raw material for which is natural gas, gas is actually imported further and with more added value for Russian producers,” Souček explains. “Moreover, we are economically destroying the European industry, because European manufacturers can’t seriously compete with Russian ones.”

The call to action is likely to receive a positive response from the Czech government which has long called for stricter sanctions on Russia—up to and including a complete ban on Russian goods and services entering the EU. However, as a trading bloc, the final decision on what chemical products can and cannot be imported lies with the politicians in Brussels.

Notably, the EU’s final push to remove Russian energy and chemical feedstock imports is proving a challenge. As a recent Reuters report notes, “While EU imports of Russian gas via pipelines have plummeted since the invasion of Ukraine in February 2022, around 19% of the bloc’s gas imports still comes from Russia through liquefied natural gas imports and via the TurkStream pipeline into central Europe.”

All the same, Brussels remains publicly committed to punishing Russia for its aggression, even if it economically also hurts domestic economic health. As Reuters explained, “The European Union last week released a roadmap for fully phasing out Russian oil and gas imports and the European Commission next month will propose legal measures to ban remaining Russian pipeline gas and LNG imports under existing contracts by the end of 2027. [Furthermore], the EU executive body will also propose a ban on new deals for Russian gas and existing spot contracts by the end of 2025.”

Ultimately, Europe’s chemical industry stands at a crossroads. What began as a geopolitical move to curb Russian aggression has evolved into a far-reaching economic challenge for one of the continent’s most vital industrial sectors. As chemical companies battle rising costs, foreign competition, and mounting regulatory pressures, the future of European chemical production hangs in the balance.

Without swift, coordinated action—whether in the form of targeted trade restrictions, strategic support for affected industries, or accelerated investment in sustainable feedstock alternatives—Europe risks not only losing a key economic pillar but also deepening its dependence on the very imports sanctions sought to eliminate.

As a result, the decisions made in Brussels over the coming months will not only shape the chemical industry’s trajectory but will also define Europe’s industrial resilience in an increasingly unstable world.

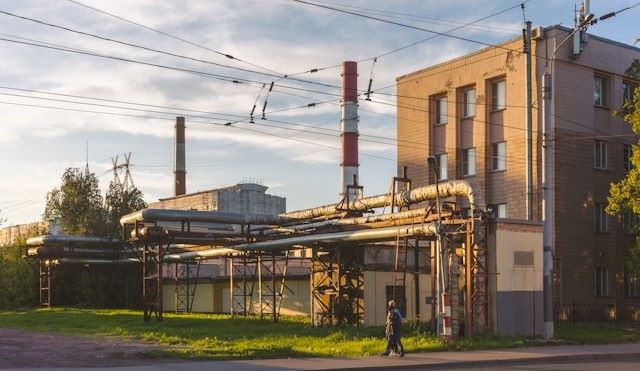

Photo credit: Wirestock on Freepik, Gencraft, Gencraft, Red Shuheart on Unsplash, & Mark Tryapichnikov