-

Does Raw Chemical Price Volatility Worry You?

Continue Reading

Continue ReadingEver since the world has had commodities, their value has been changing. For example, the global price of bronze rose year on year during the building of the Colossus of Rhodes. What worry that caused raw material traders back then we can only wonder.

As the world grew smaller and technology advanced, so raw material prices and supply volatility increased, such that during the mid 19th century ‘tea clipper’ sailing ships returning to London with the freshest tea from China caused huge market price swings based on how long the 100 day or so journey from China took, if they survived the journey at all.

Today’s trading world is even smaller; the supply volatility more dramatic; and the price changes quicker than ever before; a situation that has created ever more worry among chemical traders and procurement managers.

For traders outside the chemical industry the situation is creating even more concern. For example, in October 2014, the Wall Street Journal reported how those who paid for some stock price information services were getting their market news three tenths of a second faster than the general public, and as a result making a fortune from beating the public to the trade.

Similarly, former bond dealer, Michael Lewis tells a true story in his best-selling book ‘Flash Boys’, of how stock exchange traders were using the speed that the electronics processed transactions to their advantage. If, after hitting the ‘buy’ button, the deal was able to be completed after 4 milliseconds, then it could be blocked by a faster computer, closer to the stock market floor that could make the deal in 2 milliseconds. That 2 millisecond advantage was the difference between profit and loss. A fast blink of the eye lasts 100 milliseconds.

Fortunately, whilst industrial chemical trading is going increasingly digital it has yet to reach such speeds. But still, price fluctuations in chemical feedstock can still give traders, manufacturers and investors nightmares. But should they?

Is Industrial Chemical Feedstock Volatility really a Bad Thing?

Wouter Hut, Vice President Procurement for AkzoNobel’s Specialty Chemicals Business Area, doesn’t think so. He sees price changes and supply fluctuations as a potential advantage, stating in a recent interview that, “Raw material volatility is traditionally seen as a negative business contributor, whereas in my belief, and we have proven so, it presents an opportunity rather than a threat to margins.”

Turning volatility into an advantage isn’t easy, but with feedstock taking on average 60% of a chemical company’s total costs, industrial chemical manufacturers are very aware of the impact supply fluctuations and price changes can have. But what do procurement executives think of the problem?

Well, according to The Hackett Group’s ‘Study of Key Issues’ as published by Chemical Info, the top concern for supply chain executives (mentioned as a major or critical concern by 92% of respondents) was improving supply chain flexibility, as a means to control supply fluctuations.

This has lead to many companies sourcing raw materials from multiple suppliers, as Joshua Nelson, Director of Strategy & Operations Supply Chain Practice at The Hackett Group makes clear in the report, stating, “The emergence of supply chain risk mitigation as a key issue has caused many procurement managers to reassess their reliance on single sourcing strategies.”

Having multiple suppliers may not always be possible, but what Hut makes clear is that having a ‘world-class procurement organization’ is of ‘business critical importance’. For if a business can achieve that, then the nightmare of fluctuating chemical feedstock costs and varying supply chain challenges disappears. Instead, as Hut states, “Raw material price volatility is then no longer a threat, but an opportunity.”

You can join Wouter Hut and his discussion on ‘Fluctuating Raw Material Prices; How the industry can overcome price uncertainty and planning challenges’ at CIEX 2016, a meeting of like-minded R&D experts across the chemical value chain to discuss the challenges and opportunities that the industry holds.

Join us at CIEX 2016 and learn from over 40 hand-picked client and supplier speakers from Fortune 500 companies including Henkel, L’Oreal, Dow Chemical, Johnson Matthey, Lonza, Covestro, Evonik, Swarovski, Natura, Dupont, Ineos, DSM, McBride and many more!

CIEX is created for R&D and Innovation experts from the consumer, industrial and specialty chemical sectors. By bringing together all players in the chemical value chain, we create a unique platform for participants to learn, exchange ideas and connect with potential partners.

Join us at CIEX 2016 on Sep 28-29 in Frankfurt! Spotchemi readers benefit from 20% OFF!

To register, please visit: http://www.ciex-eu.org Use Promo code: SPOTC20

Photo credit: Mark Woodward

-

Understanding a Leaf for Improved Pesticide Dynamics

Continue Reading

Continue ReadingAgricultural scientists at the University of Manchester, England, are making groundbreaking discoveries on the way that the protective wax on leaves operates. By doing so they hope to increase their understanding of the dynamics of pesticides so that future agrichemical products are more efficient.

In research that was supported by the agrochemical company Syngenta, the researchers even constructed a model of a leaf with a replica wax coating, and by using neutron reflectometry have been able to learn about its thickness, chemical properties and how liquids penetrate this layer.

The online journal ScienceDaily explains how this was achieved, writing, “To make the model of the leaf surface, scientists first extracted real plant wax from barley and wheat leaves. This was made possible by a new technique called supercritical carbon dioxide extraction, where scientists dissolve the wax off the surface of the leaf using a carbon dioxide solvent under its supercritical condition at a very high temperature and pressure. When the pressure and temperature is reduced, the carbon dioxide evaporates, leaving behind the wax. This technique was developed in the Green Chemistry Department at the University of York.

The team from the University of Manchester then took the extracted wax and spin coated it onto a flat a silicon support in order to model the leaf surface. Imaging techniques allowed the team to see that the wax model was very similar to the structure of the wax on a real leaf, meaning the model could be used to realistically study how pesticides cross the wax barrier to get into the plant.

In a technique known as neutron reflectometry, the team used ISIS instrument, INTER to bounce neutrons off the surface of the wax model. They found that the wax was made up of a thin underlying film covered by large crystalline structures.”

When discussing the research with the open source scientific website AlphaGalileo, lead author of the study, Elias Pambou from the University of Manchester said, “Neutron reflectometry is so effective because not only can we look at the thickness of the wax films but also the change in density over the thickness range. We’re able to look at the amount of water penetrating into the leaf at the surface of the wax compared to the bottom of the wax closest to the epicuticular plant cells. That could give us a lot of information regarding how the water is diffusing through the plant.”

The research is significant given the current trend of problems that the crop protection industry is fighting. As Julian Gold, Farm Manager of the Hendred Estate in Oxfordshire outlines, “We are currently facing multiple challenges on the pesticide front as there are increasing levels of resistance developing in weeds, pests and diseases as well as a reducing pesticide armoury due to tighter conditions being imposed for registration of products.” He continued by outlining the importance of further pesticide research, saying, “Any research that can improve the efficacy of products through a better understanding of the way that diseases and pesticides penetrate the waxy layer on leaf surfaces should be incredibly useful.”

In a field of research where the study of the nanoworld is playing an ever-larger role, analysis of the crucial interaction between liquids at the leaf’s surface and the way that chemicals are and are not able to interpenetrate plant cells is part of the next wave of crop protection products. As Elias Pambou explains, “By understanding how surfactants in pesticides interact with the plant you can fine-tune the ingredients of the pesticide to not only further increase crop yield but take away some potential negative side effects, including the removal of some of the waxes which leaves the plant susceptible to other sorts of diseases and attack from bacteria and microbes. This opens the door to crop-safe formulations which will reversibly interact with the plant waxes.”

How long it will take for the improved understanding of leaf wax dynamics to produce improved crop protection products is not known, but without a full understanding of the way in which plants protect themselves previous agri-product development has always been working with an unknown x-factor.

Now that researchers have a clearer picture of a plant’s natural defences and the way that chemicals and liquids penetrate those defences, it is hoped that cheaper and more efficient agricultural products may soon be on the market.

Photo credit: David Webb, University of Hamburg

-

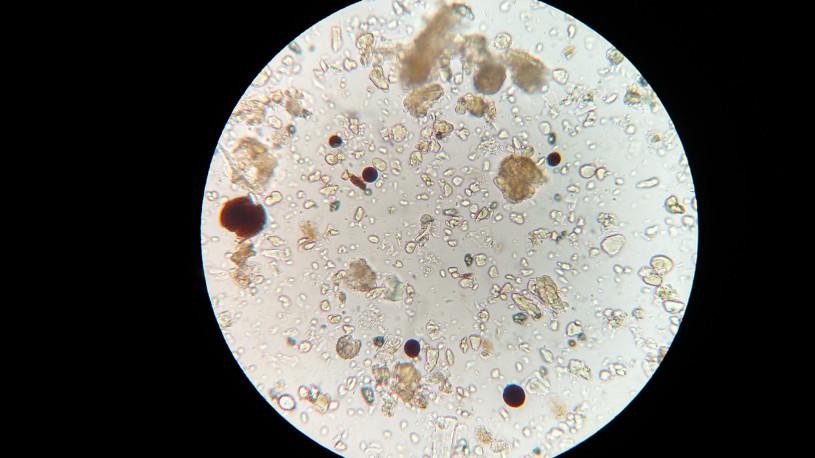

Could this Industrial Microorganism Improve Bio-Chemical Production?

Continue Reading

Continue ReadingThe improved production of numerous biochemicals, including butyric acid, is now a step closer following a comprehensive analysis of the Gram-positive, anaerobic spore-forming bacteria Clostridium tyrobutyricum . The study included the sequencing of the bacteria’s genome, opening the door for exploration into ways that the bacteria can be engineered to allow for improved biochemical production.

As the online journal Controlled Environments reports, “The team adopted a genoproteomic approach, combining genomics and proteomics, to investigate the metabolic features of C. tyrobutyricum. [Whereby] The expression of various metabolic genes, including those involved in butyrate formation, was analyzed using the ‘shotgun’ proteome approach.”

Prior to this research, little was known about the genotypic and metabolic traits of Clostridium tyrobutyricum, even though it had long been considered a potential tool for large scale biochemical production. Given the advantages that the bacteria’s metabolism has over its alternatives the study is a key step towards improved biochemical production and more economical biofuels.

The research was based at the Chemical and Biomolecular Engineering Department at the Korea Advanced Institute of Science and Technology (KAIST) whose website explained the inherent advantages of the bacteria, stating, “To date, the bio-based production of 1-butanol, a next-generation biofuel, has relied on several clostridial hosts including C. acetobutylicum and C. beijerinckii. However, these organisms have a low tolerance against 1-butanol even though they are naturally capable of producing it. C. tyrobutyricum cannot produce 1-butanol itself, but has a higher 1-butanol-tolerance and rapid uptake of monosaccharides, compared to those two species.”

By identifying the genes involved in the central metabolism of C. tyrobutyricum the study will accelerate research into how the bacterium can be engineered to replace traditional bacterial hosts in the production of butyric acid and 1-butanol.

When discussing the significance of the study, lead researcher, Professor Sang Yup Lee explained how, “The unique metabolic features and energy conservation mechanisms of C. tyrobutyricum can be employed in the various microbial hosts we have previously developed to further improve their productivity and yield. Moreover, findings on C. tyrobutyricum revealed by this study will be the first step to directly engineer this bacterium.”

You can listen to Prof Lee’s five minute talk on the topic of ‘Bio-based materials that replace petroleum-based materials’ at the World Economic Forum on YouTube here.

The title of the research paper is ‘Deciphering Clostridium tyrobutyricum Metabolism Based on the Who-Genome Sequence and Proteome Analyses’, which has been published in the online open access journal of the American Society for Microbiology ‘MBio’ (DOI: 10.1128/mBio.00743-16). The journal also acknowledged the importance of the discovery, stating, “Bio-based production of chemicals from renewable biomass has become increasingly important due to our concerns on climate change and other environmental problems. C. tyrobutyricum has been used for efficient butyric acid production. In order to further increase the performance and expand the capabilities of this strain toward production of other chemicals, metabolic engineering needs to be performed. For this, better understanding on the metabolic and physiological characteristics of this bacterium at the genome level is needed. This work reporting the results of complete genomic and proteomic analyses together with new insights on butyric acid biosynthetic pathway and energy conservation will allow development of strategies for metabolic engineering of C. tyrobutyricum for the bio-based production of various chemicals in addition to butyric acid.”

With the chemical industry’s continued reliance on fossil fuels as both a chemical feedstock and as an energy source there is a growing need for bio-based chemical production. A full understanding of the make-up and metabolic processes of key-bacteria is vital if the biochemical industry is to have a chance at replacing more traditional chemical feedstock sources.

Underlining this point is Director Jin-Woo Kim at the Platform Technology Division of the Ministry of Science, ICT and Future Planning of Korea, who oversees the Technology Development Program to Solve Climate Change, who praised the research, saying, “Over the years, Professor Lee’s team has researched the development of a bio-refinery system to produce natural and non-natural chemicals with the systems metabolic engineering of microorganisms. They were able to design strategies for the development of diverse industrial microbial strains to produce useful chemicals from inedible biomass-based carbon dioxide fixation. We believe the efficient production of butyric acid using a metabolic engineering approach will play an important role in the establishment of a bioprocess for chemical production.”

If he is correct, then maybe this bacterium will be the breakthrough for more affordable industrial chemical feedstock for everybody.

Photo credit: Wikipedia

Photo credit: YouTube