-

A Coating that can Switch between Adhesion and Non-Adhesion

Continue Reading

Continue ReadingFor many years the chemical industry has been able to make a material waterproof. Material designers have copied nature, such as the composition of a lotus leaf that prevents moisture getting in. Similarly, chemists have developed materials and coatings that produce high adhesion.

But until now, mankind has yet to create a practical material that can switch from ‘sticky’ to ‘slippery’ and back again. This is because previous research in this field has only led to the production of very fragile materials.

However, a new study has found a much more robust product that uses a layer of boron nitride and an electric current so that, as the online journal Phys.org reports, “… it can be switched back and forth between states with high and low wetting and adhesion.”

A material’s stiction (static friction) and wetting are usually dictated by the nanostructure of the surface and how it interacts with another surface, including the geometry of the atoms, but the relationship between these two states has often been little understood.

But now a breakthrough has been made, and the results published in the online journal Nature, which states that, “Stiction and adhesion can be reversibly switched by applying different electrochemical potentials to the sample [a hexagonal boron nitride monolayer on rhodium], causing atomic hydrogen to be intercalated or not.”

As one of the lead researchers, Thomas Greber from the Physics Institute at the University of Zürich, explained, “Just as the material graphene consists of only one layer of carbon atoms, our boron nitride has a thickness of only one atomic layer.”

The online journal Phys.org explained in more detail, stating that, “This ultrathin layer can be grown on a rhodium single crystal. The atoms on the rhodium surface and in the boron nitride form a hexagonal pattern, but the distances between the atoms in the two materials are different. Thirteen atoms in boron nitride take the same space as twelve rhodium atoms, so that the two crystals do not fit together perfectly. Because of this mismatch, the boron nitride hexagons must bend, they appear as a frozen wave with a wavelength of 3.2 nanometres and a height of about 0.1 nanometres.”

The ‘two-dimensional nanowave’ allows the surface to have low stiction when in contact with water. However, by putting the material in acid and applying an electrical current the surface changes. This is because, “… hydrogen atoms creep under the boron nitride layer and change the bond between nitrogen and rhodium. This makes the boron nitride flat. Suddenly the adhesion of a water drop on the surface changes dramatically – even though the drop is 100,000 times bigger than the tiny waves in the boron nitride. If the voltage is decreased, this effect is reversed.”

As a result, the materials ‘stickiness’ and ‘slipperiness’ can be freely switched back and forth.

A video clip of the experiment in progress can be seen here.

But the true discovery is in how robust this new material is, as fellow researcher Stijn Mertens of the Institute of Applied Physics at the Vienna University of Technology explained, “Our surface consists of only a single layer of atoms, is completely inorganic and does not change even if we heat it in vacuum to 1000°C. This means that this material could also be used for applications where organic molecules would long be destroyed, ranging from daily life to space travel.”

With this level of sturdiness and stability the range of uses will be wide. It is only to be seen how long it takes the chemical industry to develop the discovery further so that it can be brought to market. Whilst chemists analyse the results to confirm their validity, those of a more business way of thinking are considering what applications this discovery may have. And ultimately asking themselves; “Where would you apply a material that is reversible between the states of adhesion and non-adhesion?”

Photo credit: Michael Gasperl & John Stave

Photo credit: Marcella Iannuzzi, UZH & Ari Seitsonen, ENS Paris

-

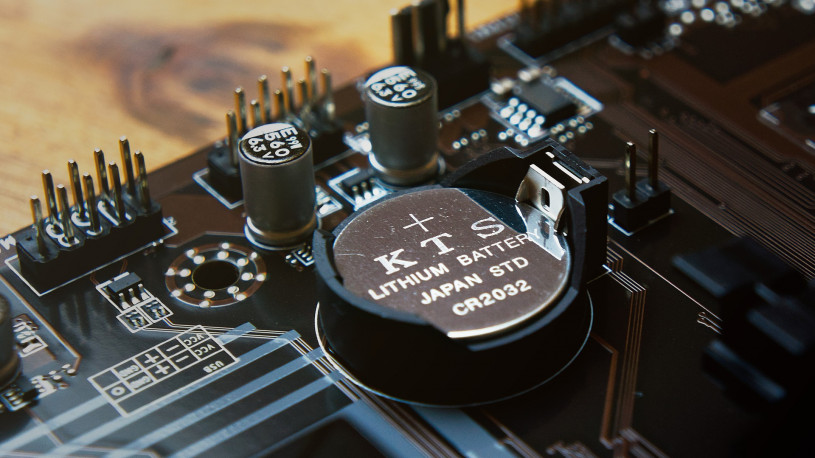

Increasing Battery Efficiency by Releasing Trapped Lithium Ions

Continue Reading

Continue ReadingThe biggest prize in the battery manufactory industry will go to the company that can produce a battery that doesn’t lose its charge over time. Whoever can develop a battery that is as effective on day one as it is on day 1,000 will possibly win a Nobel Prize and definitely win a fortune.

Now the cash and prizes are very much closer, as an international team led by Texas A&M University has published a study showing that a ‘traffic jam’ of ions may be at the root of the problem.

As lead researching chemist Sarbajit Banerjee explains, “For a battery to function properly, you need to get lithium ions in, and you need to be able to pull them out. [During the study we noticed that] Once our lithium ions got in, they sort of stopped at some point along the way.”

“You can always draw an analogy between water and electrons,” Banerjee said. “They are making these little puddles, but until the puddles are connected, they can’t flow. Once you have enough electrons coming in, they can all link up and start flowing. But until that happens, they’re all stranded, and they can’t move to charge or discharge something. And so they go out and hang in different areas of the particle. They’re all sort of sitting, defining different regions, and they aren’t able to move easily.”

As the online journal Phys.org reports, “Using one of the world’s most powerful soft X-ray microscopes—the Scanning Transmission X-ray Microscope (STXM) [the team] was able to image a traffic jam of lithium ions chemically driven through the nanowire-based channels of a simulated battery.”

As the image shows, electrons that are coupled with lithium ions can no longer move freely but instead appear ‘content to sit’. This distorts the electronic structure and traps the flow of energy. Previous research had already hypothesised that this trapped flow of energy in Li-ion cathodes existed, but up until now the blockage had never been seen.

Now the results, and images above, have been published in the journal Nature, which states that, “… in individual nanowires of layered V2O5, lithiation gradients observed on Li-ion intercalation arise from electron localization and local structural polarization. Electrons localized on the V2O5 framework couple to local structural distortions, giving rise to small polarons [the combination of a charged particle (electron) and an associated structural distortion] that serves as a bottleneck for further Li-ion insertion.”

By understanding this, the team has shown the cause of a battery’s short lifespan, and explain that if more electron-carrying lithium is to enter, then the lithium ions that are present need to diffuse. It also explains that there is the added problem that each small polaron has to carry along the structural distortion, something that will further slow down the flow of energy.

David Prendergast from the Lawrence Berkeley National Laboratory, who was also part of the discovery team, clarified this point with an analogy, saying, “Imagine wanting to move a house to a different site. A wooden house can be transported in one piece, but a brick or stone house might have to be dismantled or demolished first.”

Whilst this research is has yet to solve this house moving challenge, the study is clear evidence of where future investment needs to be made if battery lifespans are to be increased. As Banerjee notes, “There are two ways to solve the problem of moving electrons through cathode material better; one, you can make the stuff smaller or design architectures. Two, you can come up with entirely new materials, which is what we’re trying to do. Basically, you prevent the electron from getting stranded because you design the material in such a way that it doesn’t have orbitals where they would get stranded. You force them to always be de-localized. We have several materials in mind and are trying to get that research published.”

If these new materials are proven successful then the days of short battery life may be gone forever. This will not only have an impact on the small electronic devices around us, but may allow us to rethink how we use electricity everywhere; from power stations and satellites, to electric cars and the national grid. Then the question becomes not just why do batteries lose their charge so quickly, but why does anything electronic use the power it does?

As Banerjee states, “We’re trying to develop new materials to make better circuits that are less energy guzzling. This work hones in on the problem, and it’s a really good measurement.” Following this, we can ask ourselves, as Banerjee himself asks, “Why do devices like cell phones and computers use up so much energy?”

Photo credit: Kyle Wagner

-

Could This 3D Printed Polymer Bioreactor change the Chemical Industry?

Continue Reading

Continue ReadingResearchers at Lawrence Livermore National Laboratory in California have developed the world’s first reactor that can continuously convert methane to methanol at room temperature and pressure. With a technique that uses 3D printing and enzymes taken from methane consuming bacteria called methanotrophs, the team claim to have solved a key problem of natural gas production efficiency. Meanwhile, chemical traders are also studying the impact the discovery will have on methanol prices, as the product is a key chemical feedstock in polymer and paint manufacturing.

At present companies extracting natural gas, which often has a high methane content, have trouble storing and transporting the gas. As a result, much of it leaks into the atmosphere or is flared off. Estimates by the BBC calculate that as much as 20% of ‘the enhanced greenhouse effect’ is caused by methane emissions, converting waste methane to methanol could help combat climate change and aid the energy and chemical industries.

To make use of the methane, producers convert the gas to methanol, a more manageable liquid. However none of the conversion processes, such as steam reformation, are very efficient as they require high temperatures or pressure. As a result, many smaller gas drilling facilities make no effort to recoup excess methane.

But now a breakthrough has been made that may allow for cost-effective conversion on site at even the smallest, so called ’stranded‘, gas production facilities.

Explaining how the new process works, the online journal Phys.org, reports that, “The only known catalyst (industrial or biological) to convert methane to methanol under ambient conditions with high efficiency is the enzyme methane monooxygenase (MMO), which converts methane to methanol. The reaction can be carried out by methanotrophs that contain the enzyme, but this approach inevitably requires energy for upkeep and metabolism of the organisms. Instead, the team [at LLNL] separated the enzymes from the organism and used the enzymes directly.” By doing this, the team found that, “…isolated enzymes offer the promise of highly controlled reactions at ambient conditions with higher conversion efficiency and greater flexibility.”

The researchers published their results in the journal Nature Communications to explain how the conversion was made by, “Using particulate methane monooxygenase (pMMO), to create a biocatalytic polymer material that converts methane to methanol, [and by then] embedding the material within a silicone lattice to create mechanically robust, gas-permeable membranes, and direct printing of micron-scale structures with controlled geometry.”

Sarah Baker, project lead and chemist at LLNL, was shocked at the results, saying, “Remarkably, the enzymes retain up to 100 percent activity in the polymer.”

The significance of the discovery was made clearer by Joshuah Stolaroff, an environmental scientist on the team, who explained that, “Up to now, most industrial bioreactors are stirred tanks, which are inefficient for gas-liquid reactions. [Whereas] The concept of printing enzymes into a robust polymer structure opens the door for new kinds of reactors with much higher throughput and lower energy use.”

Baker adds that, “The printed enzyme-embedded polymer is highly flexible for future development and should be useful in a wide range of applications, especially those involving gas-liquid reactions.”

So it seems that the full implication of the research has yet to be seen, but already some industry experts are predicting that such an efficient and easily reproducible and practical solution could find its way not only into gas fields, but also landfill sites. The efficiency of the process has yet to be independently tested, but the research team are confident of their study, and even claim that, “The 3-D-printed polymer could be reused over many cycles and used in higher concentrations than possible with the conventional approach of the enzyme dispersed in solution.”

Whilst scientists everywhere hope that the process can soon be adopted by industry to lower human impact on climate, many in the gas drilling and exploration industry hope that it will make smaller gas reserves more efficient to tap as well as increase their profits in larger fields. The 3D printing industry is also due to take note, whilst chemical traders everywhere are already looking for the discovery’s impact on methanol prices.

photo credit: Sarah Sirajuddin, Amy Rosenzweig and Sarah Baker (LLNL)