Self-Healing, Antimicrobial Plastics from Plants

3D printed polymer feedstocks can now be greener, cleaner, and self-repairing.

Imagine a polymer that heals itself, resists microbial contamination, remembers its shape, and can be printed at room temperature using nothing more than light. Now imagine that this same material is made from renewable plant sources without the need for solvents or toxic catalysts.

Unbelievable? Well, chemical researchers have achieved exactly that, opening a new horizon for sustainable raw materials in the polymer industry.

The discovery sits at the intersection of green chemistry and advanced manufacturing, and signals a future where increasingly specialised polymer products become the norm to match consumer demand.

“The polymers we have developed are unique because they are made from plant-based compounds, cured under UV or visible light, and do not require catalysts for processing,” explains Professor Jolita Ostrauskaitė from the Kaunas University of Technology (KTU), Lithuania where the breakthrough was made. The use of vitrimers, a relatively young class of polymers first described about 30 years ago and formally recognised in the past 15 years, was key to creating the innovative plastic.

“Vitrimers are thermosetting polymers that, thanks to dynamic covalent bonds, can be thermally reprocessed or reshaped, similar to thermoplastics,” says Prof. Ostrauskaitė. “At certain temperatures, they can self-heal after damage and also retain a temporary shape that can later be restored – this is known as thermally responsive shape memory.”

These factors make them highly attractive in the drive for circular, sustainable materials — combining the durability of thermosets with the reprocessability of thermoplastics.

As the new vitrimers are formulated entirely from plant-derived compounds and cured by UV or visible light this innovative industrial feedstock eliminates the need for solvents or chemical catalysts, reducing toxicity and energy consumption. This aligns it directly with the principles of green chemistry and sustainable production.

But more significantly for plastics manufacturers, are the unique selling points which the polymer can provide. These include:

1. Antimicrobial Functionality

By incorporating structural fragments derived from plant oils and biodiesel by-products, the polymers naturally inhibit microbial growth. Lab tests confirmed strong antimicrobial activity against common microorganisms, making them promising for hygienic applications in healthcare and consumer products.

2. Self-Healing and Shape-Memory

Thanks to their dynamic covalent structure, these polymers can heal micro-cracks or re-bond when exposed to heat. They also display shape-memory behaviour, meaning they can temporarily hold a deformed state and later return to their original form when triggered by temperature.

3. 3D-Printing Compatibility

Perhaps most striking is the compatibility with optical 3D printing at room temperature. Using UV or visible light, the KTU team successfully printed a precision Y-shaped medical connector — demonstrating the polymer's potential in medical devices, electronics, and optics. Printing at ambient conditions minimises energy use and waste while enabling high-precision components.

“Such multifunctional and sustainable solutions are still very rare,” observes Ostrauskaitė, “making this an important step forward both scientifically and industrially.”

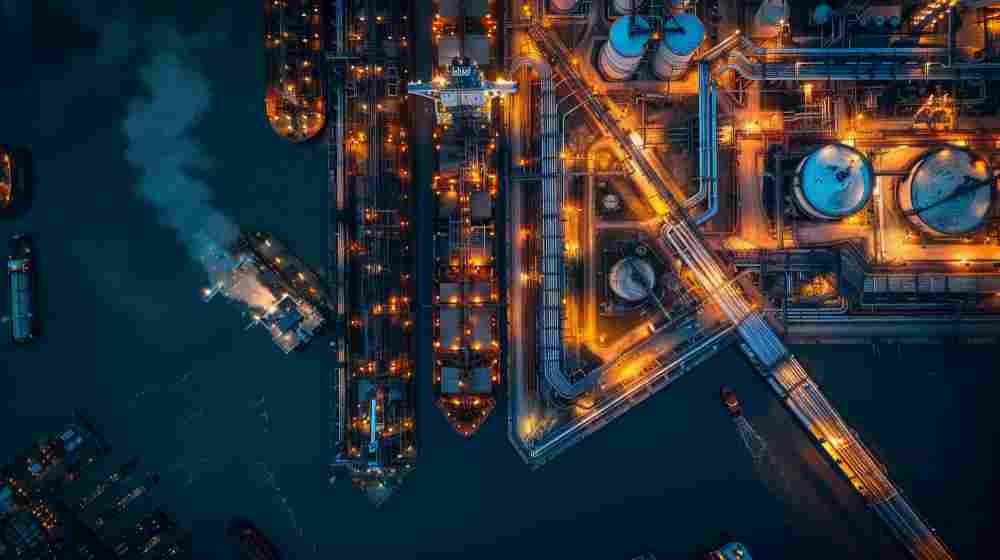

Related article: How China’s Oil to Coal Switch is Reshaping Chemical Prices

This gives them great potential for use in medical devices (making sterile, self-repairing connectors and implants), electronics (for antimicrobial, high-precision parts with repairability), and in additive manufacturing (printing sustainable, low-energy polymers for prototypes and functional components).

“We successfully printed a Y-shaped connector – a typical medical component used to join tubes in infusion or respiratory equipment,” notes the professor. “This part requires high precision, making it an excellent test of the material we developed.”

While the research is still at an early stage, the implications are far-reaching. The next steps include scaling production, testing under real-world conditions, and aligning with regulatory frameworks for medical and industrial use.

As the global polymer industry searches for greener, smarter materials, the development of sustainable, self-healing, antimicrobial vitrimers represents more than a laboratory success — it is a blueprint for the next generation of polymers. By merging renewable feedstocks, dynamic chemistry, and advanced processing, these materials promise to reshape how we design and use plastics across multiple high-tech sectors.

Photo credit: Minkus on Unsplash, Freepik, Gencraft, & Freepik